Index

sprungmarken_marker_117

What Are reFuels?

Apart from the energy sector, industry, and private households, private and goods traffic based on fossil fuels contributes significantly to anthropogenic CO2 emissions, and, hence, to climate change. When considering the climate protection goals of the Federal Government, ship, air, and rail traffic for transporting heavy goods over long distances will continue to need liquid fuels in future.

Regeneratively produced fuels, reFuels for short, have the same energy density as fossil fuels. Their use, accompanied by additional measures to expand electric mobility, represents a promising approach to CO2-neutral mobility. reFuels can be produced from carbon-containing agricultural and forestry residues or industrial and municipal waste as well as by direct conversion of CO2 and sustainably produced hydrogen.

Relevance and Necessity

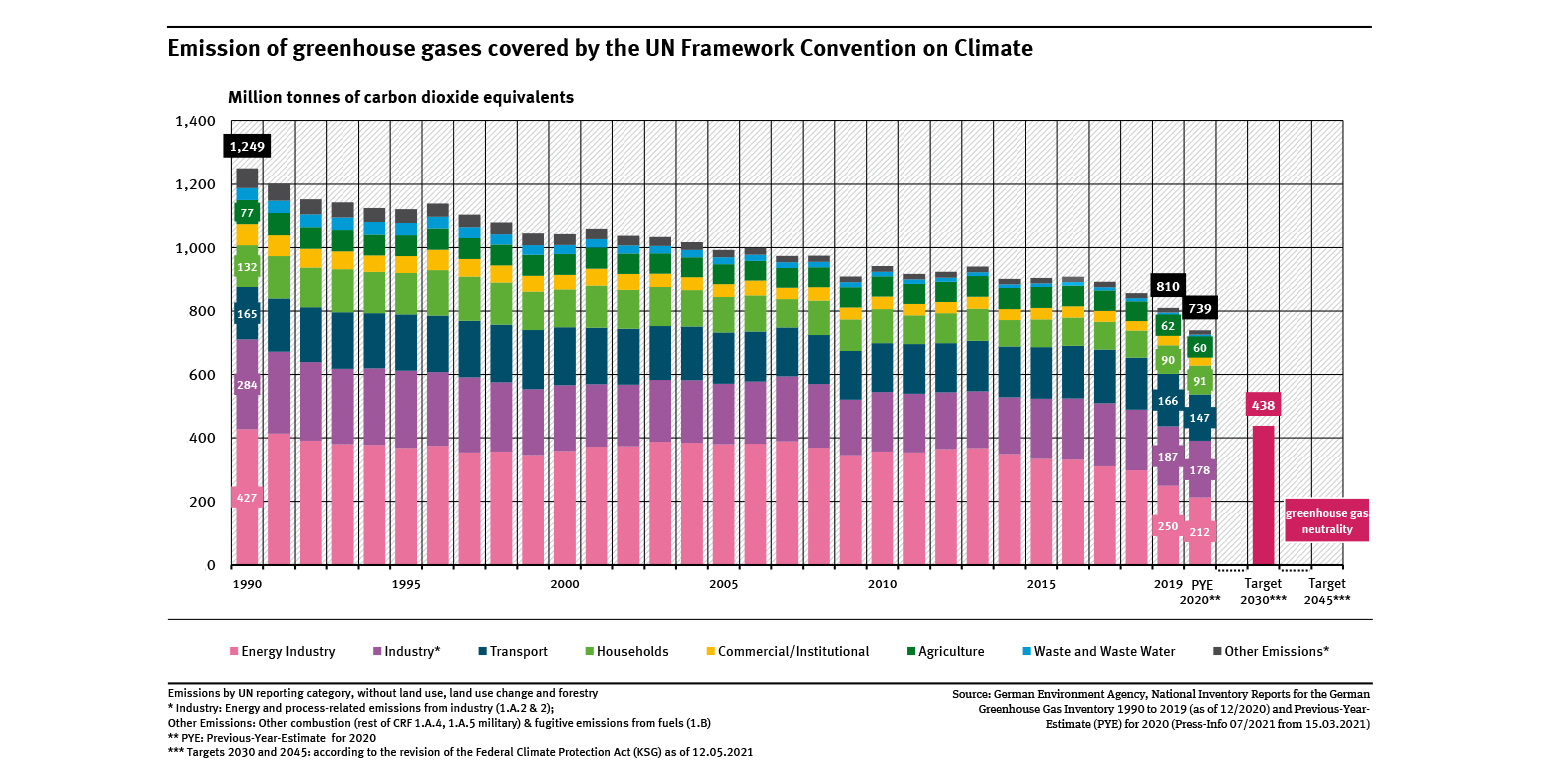

With progressing energy transition and the implementation of the climate protection plan 2050, the different areas of life, such as industry, households, or agriculture, have developed differently: CO2 emissions of the energy sector and buildings in 2017 were far lower than in the reference year of 1990. In the transport sector, by contrast, CO2 emissions stagnate in spite of the simultaneous increase in person- and ton-kilometers.

Emission of greenhouse gases in Germany

Source: UBA, www.umweltbundesamt.de/en/image/emission-of-greenhouse-gases-covered-the-un

Source: UBA, www.umweltbundesamt.de/en/image/emission-of-greenhouse-gases-covered-the-un

reFuels as Building Blocks for CO2-neutral Mobility

To largely contribute to reaching the energy transition goals in the mobility sector as well, both production processes of regenerative fuels and drive technology must be further developed. Analysis of scenarios for the transport sector reveals that a complete energy transition by 2050 will not be achieved by electric mobility alone.

Change to CO2-neutral mobility is no decision among different drivetrain concepts (electric mobility, fuel cell mobility, regenerative gaseous mobility, and regenerative fuel mobility). The different methods of producing regenerative energy have to be analyzed in parallel. The respective efficiencies, availabilities, and potentials have to be combined. A sufficient amount of CO2-neutral fuels will only be ensured when combining various processes.

Advantages

- reFuels are free from undesired minor constituents, such as sulfur or nitrogen compounds.

- The structure and composition of reFuels can be adjusted and optimized for specific applications, in particular in terms of efficiency of combustion and formation of local emissions.

- As the project focuses on hydrocarbon components, reFuels can be integrated into presently used fuels.

- The high energy density of liquid fuels and their easy storability and transportability are guaranteed when using reFuels.

- The existing transport infrastructure, logistics, and application technologies can be used as long as the fuels fulfill existing standards.

- Use of existing infrastructures and renewable energy sources for the production of reFuels will reduce CO2 emission of the existing fleet, the clear objective being CO2 neutrality.

How can reFuels be synthesized?

KIT possesses two plants for the synthesis of refuels:

The bioliq® plant on KIT’s Campus North processes straw to produce synthetic gasoline of the second generation, so-called advanced biofuels. Contrary to biofuels of the first generation, synthesis of these advanced biofuels does not compete with the production of foodstuff and feedstuff on agricultural areas.

Find out more about bioliq®.

At the neighboring Energy Lab 2.0 of KIT, e-fuels are produced by the electrolysis of water using regenerative power and CO2. The main goal is to produce kerosene. In addition, diesel and gasoline fractions are obtained. The CO2 produced when combusting e-fuels is compensated by using CO2 from ambient air or biogenic sources for their production.

Find out more about the Energy Lab 2.0.

Find out how reFuels can be synthesized in this presentation.